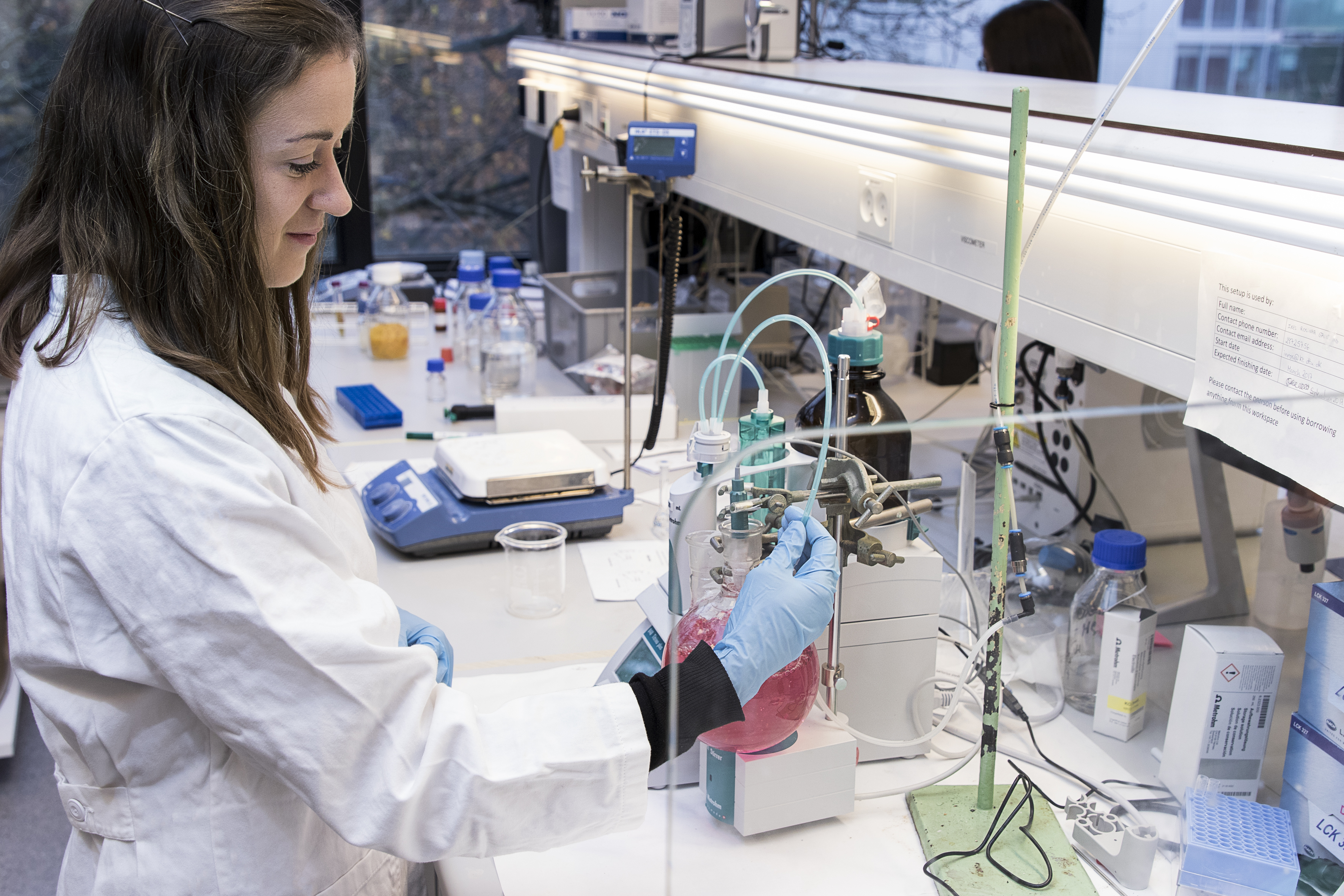

Interested in a research cooperation?

We cooperate with Danish industry, research-based international companies and acknowledged universities around the globe all working within chemistry, biotech, pharma, foods and energy.

Contact us if you would like to know more about cooperation opportunities.

Learn more about cooperation opportunities