Projects

At PROSYS we research in Process Systems Engineering where we develop model-based tools and methods for solving complex problems in (bio) chemical products and processes. We also focus on research activities, where intensified/integrated processes contribute to more resource-efficient processes and production concepts.

Projects by PROSYS

Inno4Vac is a public-private partnership that addresses scientific bottlenecks in vaccine development. It proposes to develop predictive biological and mathematical models of vaccine performance and bio-manufacturing.

Artificial intelligence combined with big data and computational modelling will be used to build an open-access and cloud-based platform for in silico vaccine efficacy assessment and development.

Controlled human infection models and cell-based human in vitro 3D models will be developed to enable early evaluation of vaccine efficacy and prediction of immune protection.

Finally, for vaccine bio-manufacturing the goal is to establish an open source in silico simulation platform for guiding the production of vaccine candidates and associated stability testing. PROSYS is involved in this last activity, where we work on development of models for upstream processes.

The consortium consists of 43 partners. The project is split up in 4 main activities. PROSYS is active in ST4 (VAXinS) - Bio-manufacturing platforms using mathematical modelling.

Contact

Krist V. Gernaey Professor Department of Chemical and Biochemical Engineering kvg@kt.dtu.dk

CALIMERO is a project funded in the topic HORIZON-CL6-2021-ZEROPOLLUTION-01-06 by the EU, whose goal is to improve current Life Cycle Sustainability Assessment (LCSA) methodologies of biobased industries, as European industries are a main source of pollution. The project aims to establish a frame for bio-based industries to evolve in all PEF indicators, plus those added by CALIMERO. The consortium will count on primary data from industrial case studies from construction, woodworking, textile, pulp & paper and biochemicals to identify and propose sectorial and cross-sectorial solutions to tackle sustainability hotspots. With these data and analysis in hand, specific guidelines and recommendations will be developed. The objective is to contribute to a more sustainable economy and to spread these guidelines for other industries to follow the lead.

The consortium is formed by 12 partners from 7 countries: Contactica S.L (Spain); Fundación Centro de Servicios y Promoción Forestal y de su Industria de Castilla y León (CESEFOR) (Spain); WELOOP (France); NEOVILI SAS (France); Association TECHTERA Auvergne Rhône Alpes (France); European Cellulose Insulation Association (Belgium); Svenska Miljoeinstitutet AB (Sweden); ESSITY Hygiene and Health AB (Sweden); BIM Kemi Sweden AB (Sweden); Danmarks Tekniske Universitet (Denmark); Luxembourg Institute of Science and Technology (Luxembourg); EREKS Blue Matters (Turkey).

Project linkedin

Contact

Gürkan Sin Professor Department of Chemical and Biochemical Engineering Phone: +45 45252980 gsi@kt.dtu.dk

Evaluation of Resource recovery Alternatives in South african water trEatment systems (ERASE)

Objective

- Development (and validation) of process models of specific resource recovery technologies specifically for South African treatment plants;

- Interfacing these new models within plant-wide approaches;

- Demonstrating novel process simulation and scenario analysis options using specific (full-scale) case studies (Cape Flats, Darvil, Zeekoegat);

- Development of a set of decision support tools based on multi-criteria decision-making and life cycle assessment;

Background

Resource recovery is an emerging research area that has promoted the development of multiple process units promising the transformation of residues into valuable products. Nevertheless, process engineers encounter problems when deciding to go for one (or another) technology when upgrading process flow diagrams.

The Project

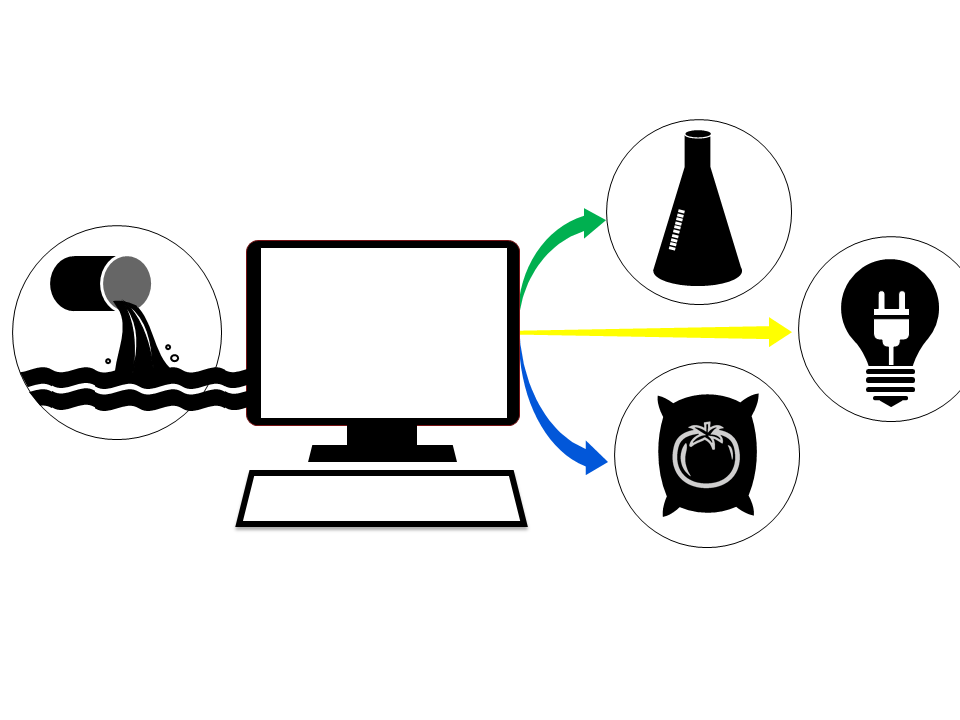

The ERASE project seeks to demonstrate the benefits of transiting from wastewater treatment plants (WWTP) to water resource recovery facilities (WWRF) amongst water utilities in South Africa. Fundamentally, the project will deliver a new generation of engineering tools to simulate resource recovery options in selected South African plants and to evaluate these novel technologies in line with the objectives of the sustainability and circular economy paradigm.

Contact

Krist V. Gernaey Professor Department of Chemical and Biochemical Engineering kvg@kt.dtu.dk

Contact

Objective

The project aims to understand the effect of dynamic non-natural conditions (such as those found in industrial equipment) on enzyme and protein stability and intends to re-design and develop new tools/equipment for successful implementation of biocatalytic processes.

Background

The application of biocatalytic processes in the industry is rapidly increasing as its seen as an essential route to sustainability. However, the true potential of biocatalysis is far from being realized. The major bottleneck to the implementation of the biocatalytic process is the poor stability of the enzymes. Much is known about enzyme stability under laboratory conditions, but the stability of the enzyme under non-natural conditions, especially outside the confines of the cell, is poorly understood. In an industrial setting, enzymes are exposed to many operating conditions not usually encountered in nature, this includes a fluid-fluid interface (gas-liquid or liquid-liquid interface), and dynamic heterogeneities observed in a large industrial reactor due to longer mixing times. These conditions can lead to the unfolding of enzymes resulting in a loss of stability. The methods for measuring enzyme stability today are focused on the stability in a static environment, the challenge of this project is to understand the effect of dynamic conditions on enzyme stability.

The Project

FLUIZYME aims to provide sufficient information for understanding enzyme stability at every scale, provide new approaches to investigate biocatalyst potential, and alternative tools. It will utilize enzymes like lipases, and different oxidoreductases such as dehydrogenases, and oxidases. Novel tools and apparatus will be developed to investigate the effect of indirect and direct fluid-fluid interface exposure on enzymes, along with different mixing and cycling times.

Novel apparatus will be designed that represents a small, homogenous part of a reactor and will be employed to mimic conditions observed on a large scale. Furthermore, a model will be created by using the results from the small-scale experiments, and a prediction study at a larger scale will be done. Here, models will focus on enzyme stability vs. time, the second phase hold up, and other parameters. The resulting model will be applied at the pilot scale. In parallel, the corresponding experimental and computational methods will be consolidated into a generic platform of technologies for fast and accurate enzyme stability determination required for process optimization, production, and application of biocatalytic processes. Discoveries via FLUIZYME will enable the implementation of new enzymology for highly efficient biocatalysts for industrially important conversions.

The EC-funded FLUIZYME project brings together collaborations from across- and beyond Europe, including researchers from the University of Groningen NL, University of Manchester UK, Georgia Tech USA, Technical University of Munich, KTH, Shanghai Jiao Tong University China and DTU. The research for this work has received funding from the European Research Council (ERC) project FLUIZYME (Grant agreement no 101021024) under the EU’s Horizon 2020 research and innovation programme.

Objective

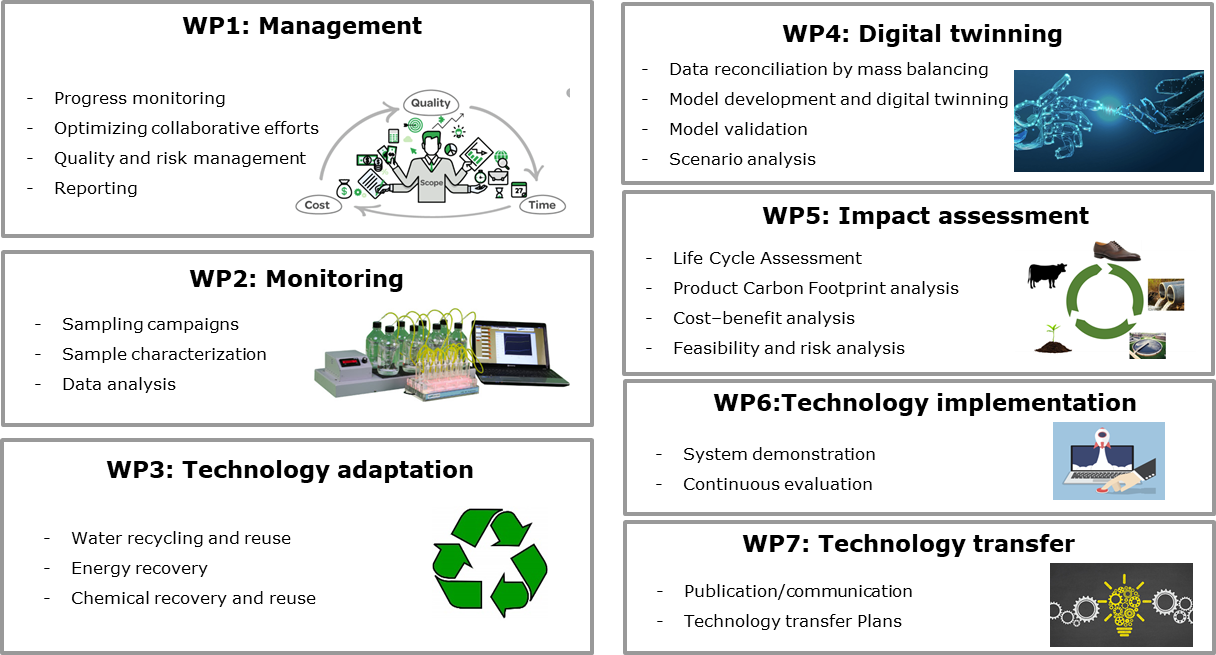

The overall aim of the GreenTan-project is to promote circular economy in the leather (tannery) industry through recycling, recovering and reusing water and energy i.e. creating nearly zero waste tannery. Our approach is to target radical improvements to obtain multi quality recycled streams for reuse and recovery purposes

Background

Leather production is one of the most water-intensive and polluting industries across the globe. Each year tanneries consume excessive quantities of water for leather production, employing toxic substances, such as sulfide and chromium, and generating effluents with high levels of contamination. Leather industry annually consumes 229 billion liter of water and emits more than 100 billion kilograms of CO2. This issue has been addressed in a recent report by United Nations Industrial Development Organization, highlighting the significance of water demand by industrial tanneries

The Project

In this project, following objectives (OBJ) are defined:

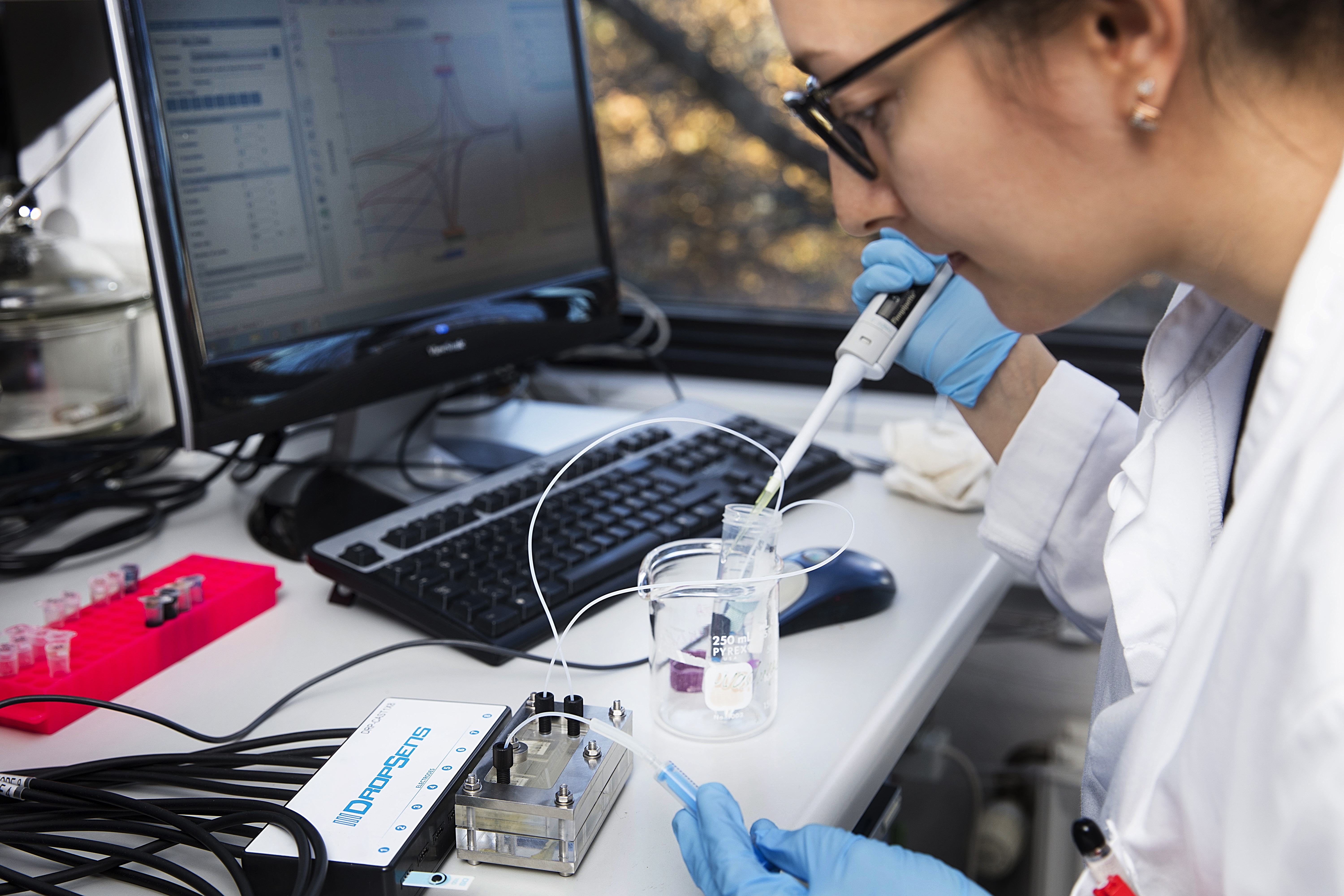

- OBJ1: Select and adapt suitable technologies (e.g. nanofiltration and electrolysis) for reuse and recovery purposes in tannery industry by thorough monitoring and in lab-scale and pilot scale

- OBJ2:Create multi-criteria solutions for implementation of suitable technologies by digital twin modelling, process integration and data analysis.

- OBJ3: Impact assessment to identify opportunities and risks with relation to process efficiency and environmental footprints using life cycle assessment and cost-benefit analysis

- OBJ4: Implement and operate selected suitable technologies at the full-scale while preparing for further commercialisation.

Contact

Jens Abildskov Associate professor Department of Chemical and Biochemical Engineering Phone: +45 45252907 ja@kt.dtu.dk

Contact

Pedram Ramin Senior Researcher Department of Chemical and Biochemical Engineering pear@kt.dtu.dk

Contact

Elham Ramin Researcher Department of Chemical and Biochemical Engineering elhr@kt.dtu.dk

Contact

BIOPRO World Talent Campus 2023

The World Talent Campus will be held in the greater Copenhagen area in Denmark from Saturday 16 September to midnight Friday 22 September 2023.

The application must include:

- 1 page - application letter including educational background and personal motivation

- 1 page - description of PhD project or Master thesis

- 1 page - faculty support letter

- Documentation of grades

- CV

About BIOPRO WTC

Every year, we invite research talents from all over the world for a competition across disciplines.

The World Talent Campus is an advanced one week course at PhD level, where students will learn and be challenged with cutting edge knowledge within biotechnology manufacturing.

The course will focus on bioprocess monitoring and optimization, by addressing e.g. online measurement techniques, development and implementation of sensors in large-scale facilities, chemometrics as well as soft sensors based on mechanistic models.

The course will also include social events and team building activities in order to foster the creation of a global network.

25 PhD or Master students working in the field of biotechnology manufacturing, from 20 selected universities around the world, will participate.

Contact

Krist V. Gernaey Professor Department of Chemical and Biochemical Engineering kvg@kt.dtu.dk