Intumescent coatings

Saving lives

In the event of a fire in buildings, airports, skyscrapers or oil rigs, the temperature of unprotected steel may rise to a point (400-500 °C), where the probability of structure collapse becomes prohibitively high.

To avoid such incidents, so-called intumescent coatings are used as passive fire protection.

Under the influence of heat, an intumescent coating swells up to 50 times its original thickness and forms a multicellular char layer, which protects (insulates) the steel.

This allows people more time to escape the burning building or production site.

Char development

Intumescent coatings are comprised of five basic compound groups (blowing agents, acid- and carbon sources, binders, and pigments), which all contribute to the char formation process.

The physical and chemical interactions between the different compounds are very complex and require a battery of analytical techniques and modelling tools for proper characterization.

Research in this field aims at a better understanding of the mechanisms for char formation, including the important parameters providing a stable and mechanically strong char.

Methods to replace problematic compounds are ongoing, and the design and formulation of entirely new intumescent coatings is a constant challenge.

Disciplines

Disciplines involved in understanding the working mechanisms of intumescent coatings are chemical reaction kinetics, rheology, advanced analytical and characterization tools, materials science, mathematical modelling, as well as transport phenomena.

Projects

The project

Despite their century-long use in fire protection, the precise operational mechanisms and chemical reactions of intumescent coatings are not fully understood, hindering their optimization. This project aims to deepen this understanding by developing mathematical models to explain their protective swelling under heat. We employ analytical techniques like Simultaneous Thermal Analysis (STA) to examine the chemical reactions, using this data to build detailed reaction models. These, in turn, form the basis for predictive models of coating performance in fire scenarios. Enhanced understanding can lead to improved coating designs, ultimately increasing fire safety and saving lives.

Funding

Hempel Foundation. The project runs from 23.10.2023 to 23.10.2026.

Supervisors

- Søren Kiil

- Jochen Dreyer

Contact

Jan Bartlomiej Krzak Research Assistant

Contact

Søren Kiil Professor Department of Chemical and Biochemical Engineering sk@kt.dtu.dk

Objective

This project aims to develop characterization methods which allows a mapping of the internal structure of epoxy intumescent char. Subsequently,a formulation-testing strategy can be designed in order to develop coatings with optimal char structure.

Background

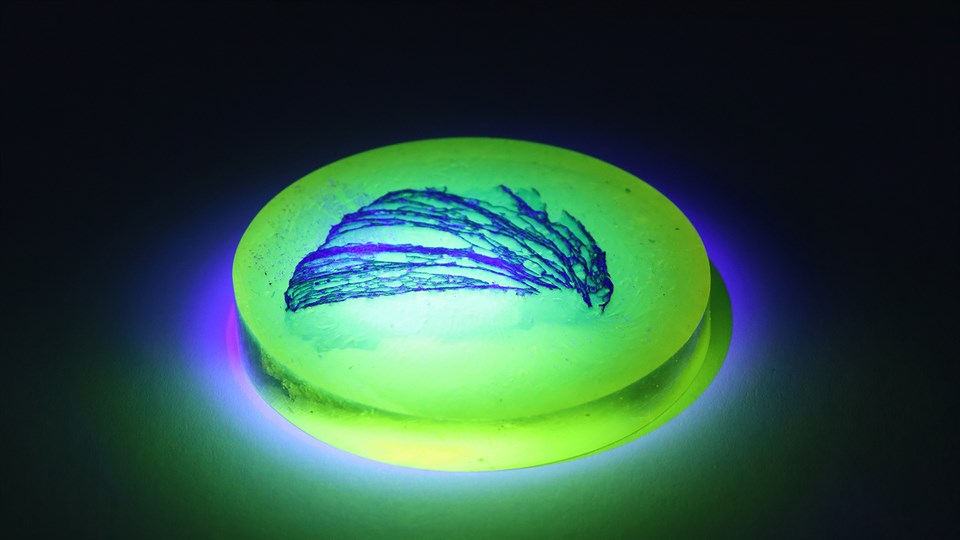

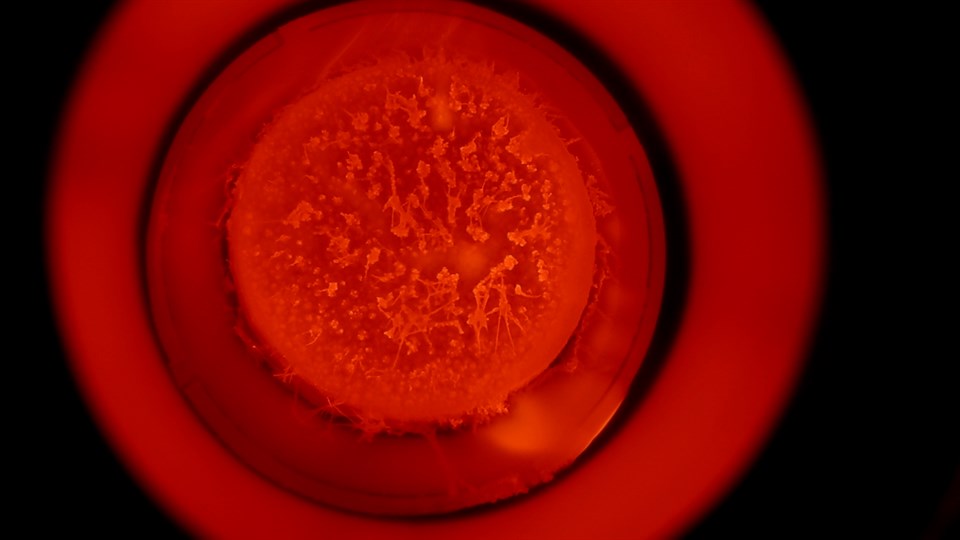

In the event of fire, intumescent coatings can develop a thermal insulating char, which can protect load-bearing steel structures in buildings or offshore platforms. As a result, longer escape times are bestowed to people. The char formed consists of a porous, multicellular structure whose thermal insulation properties depends not only on porosity, but also on pore size distribution, pore connectivity, pore shape and the presence of cracks or other defects.

Previous researches on internal characterization of intumescent chars faced two main challenges: the fragility of the material and the low contrast between solid and void when viewed by camera or microscope. These facts lead to unrealistic values regarding the internal structural parameters of the char.

The project

The purpose of the project is to develop characterization methods which allow mapping and quantifying in a efficient manner parameters such as pore size distribution, pore shape, porosity and pore connectivity. Three characterization methods, all relying on image recording, are proposed in this project:

- X-Ray tomography

- Digital microscope with fluorescent imaging

- Scanning Electron Microscope

The above methods have advantages and disadvantages, and a combination of them may turn out to provide the best results.

Besides, the optimal pore size distribution will be assessed from a theoretical point of view, either by mathematical models or information found in literature from similar materials (i.e. ceramics).

The final goal of the project is to develop a formulation-testing strategy which gives the optimal char structure.

Funding

The Hempel Foundation, the Technical University of Denmark (DTU) and HEMPEL A/S

The project runs from 15 May 2022 - 14 May 2025.

Supervisors

Søren Kiil, Professor at DTU (main supervisor)

Jochen A. Dreyer, Assistant Professor at DTU (cosupervisor)

External supervisor

Dipak Mistry, PFP Technical Manager at HEMPEL A/S

Jeanine C. Pichler, R&D Scientist at HEMPEL A/S

Contact

Ander Labaien Etxeberria Postdoc Department of Chemical and Biochemical Engineering anletx@kt.dtu.dk

Contact

Søren Kiil Professor Department of Chemical and Biochemical Engineering sk@kt.dtu.dk

Contact

Kim Dam-Johansen Professor Department of Chemical and Biochemical Engineering KDJ@kt.dtu.dk

Objective

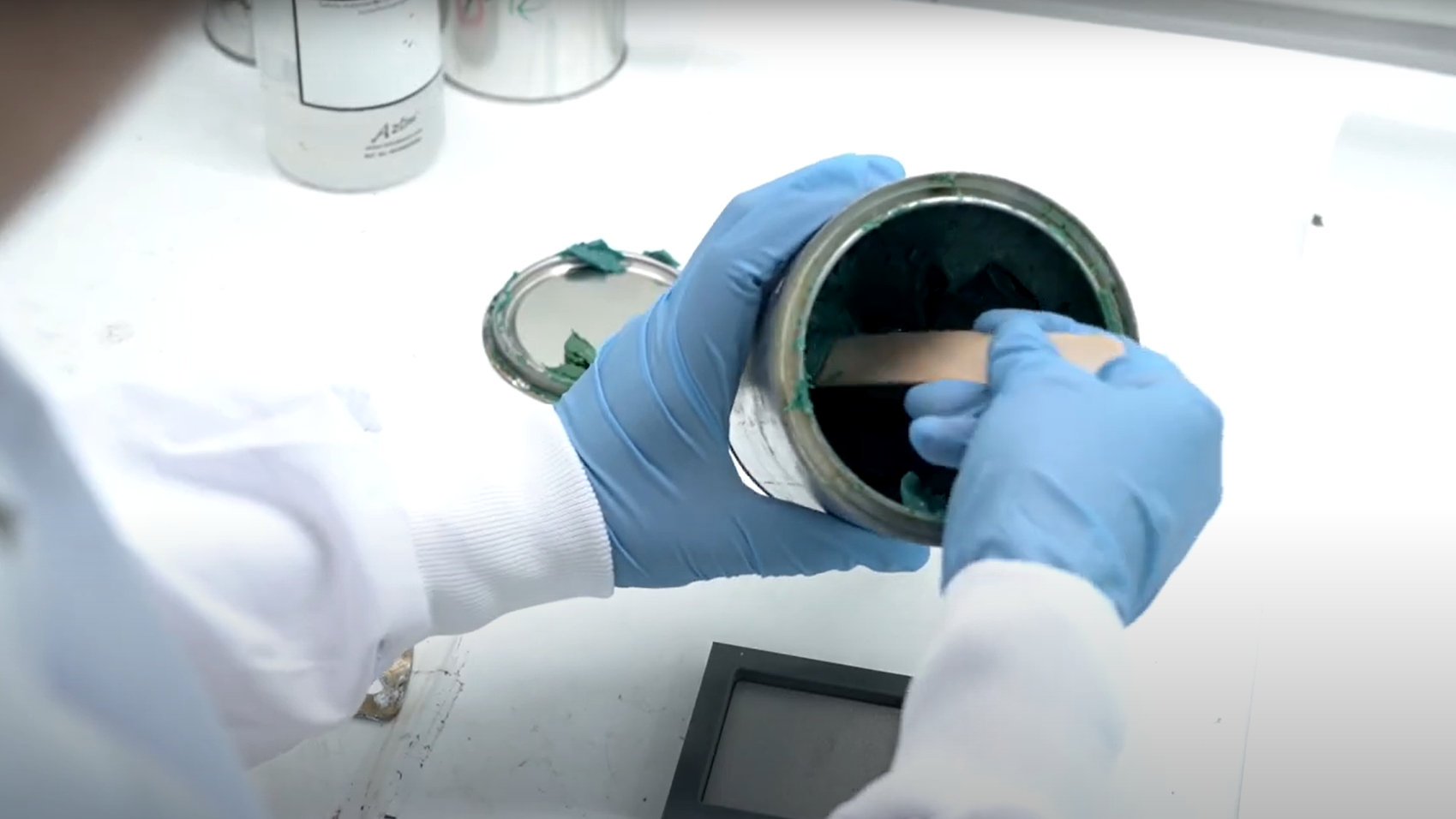

The objective of this work is to develop new intumescent coating formulations, which are better than the current-state-of-the-art commercial coatings in terms of fire protection.

Background

Fire protection of structures is of upmost importance to save lives and property in the event of fire. One promising way of protecting steel is by using intumescent coatings. Current state-of-the-art commercial intumescent coatings are mainly based on organic constituents. These suffer from disadvantages such as toxic species incorporation, toxic gas release, low mechanical strength of the expanded char, and exothermic decomposition. Therefore, alternatives are sought.

The project

- Evaluate current state-of-the-art commercial intumescent coatings

- Develop a simple burner testing facility for intumescent coatings

- Prepare and test novel intumescent coating formulations

- Prepare and test novel intumescing materials

- Optimize novel intumescent coating formulations

Funding

Sino-Danish Center for Education and Research (SDC) and the Hempel Foundation. The project runs from 15 April 2022 - 14 April 2025.

Supervisors

- Kim Dam-Johansen (main supervisor)

- Hao Wu (co-supervisor)

Contact

Hafeez Ahmadi Postdoc Department of Chemical and Biochemical Engineering hahm@kt.dtu.dk

Contact

Kim Dam-Johansen Professor Department of Chemical and Biochemical Engineering KDJ@kt.dtu.dk