Sustainable raw materials for coatings

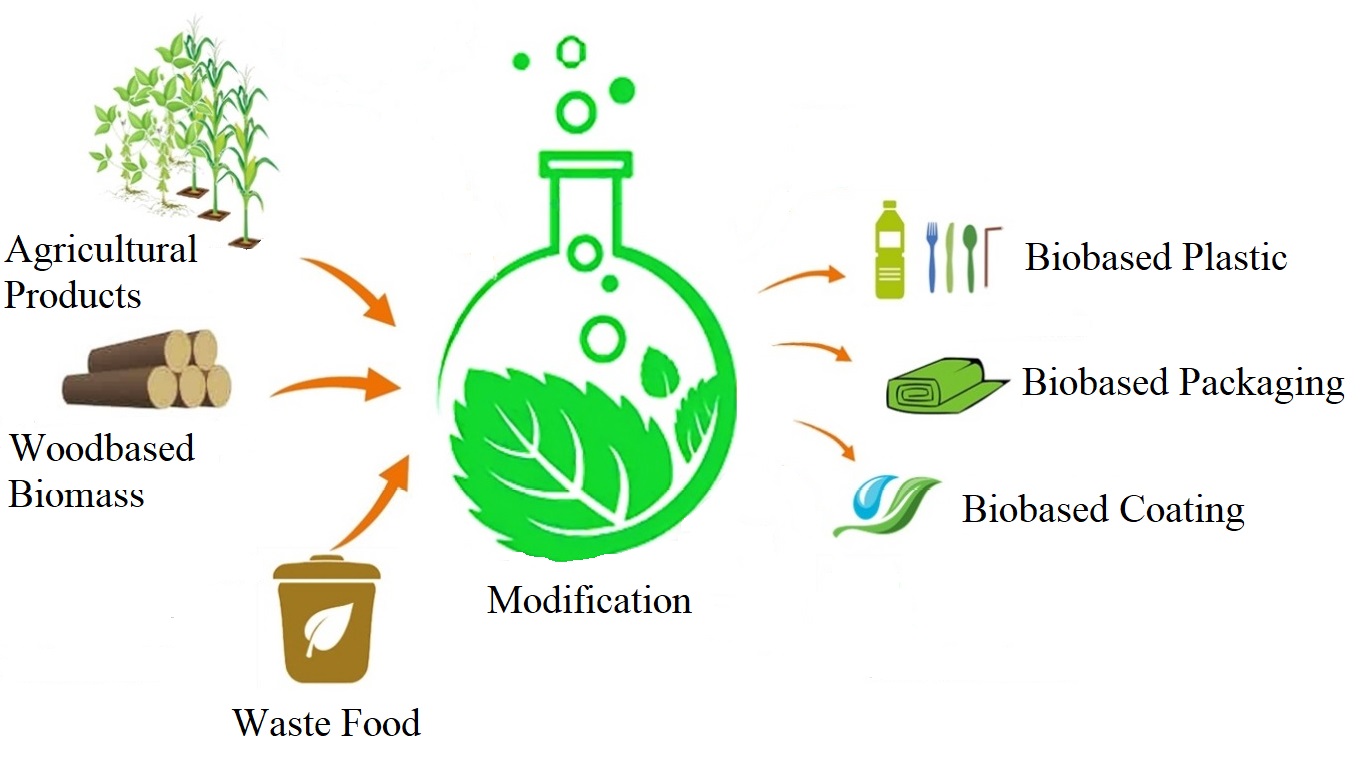

Working along the entire value chain, we aim to replace fossil-based materials with sustainable raw materials to minimize the CO2 footprint and improve the sustainability profile throughout the coating lifetime.

Coatings for a better future

We are driven by a desire to develop coatings for a better future. We strive to protect our environment by developing new less polluting and more sustainable coating solutions to the benefit of the society.

Improved sustainability profiles by utilizing industrial leftovers

Our purpose is not only to reduce the use of fossil fuels by using bio-based raw materials in the coatings. We also aim to eliminate the use of hazardous materials, introduce bio- renewables, incorporate recycled materials and lower VOC emissions.

Not least, we have an overall focus on developing bio-based coatings which performances are superior to those of traditional coatings throughout their entire lifetime.

Disciplines

Chemical reaction engineering, polymer chemistry, enzymes, coating formulation, degradation of biomass.

Projects

Why: We need an "easy to use" tool to tell how sustainable a coating/coating system is.

What: The project is to get a quantitative understanding of how to assess sustainability in coatings and create an "easy to use" operational model - A sustainability index.

How: In order to be able to develop the assessment method for the coating system it will be necessary to analyse the coating life cycle in detail. This includes several steps which needs to be evaluated individually:

- Identify hotspots in the coating life cycle.

- Develop assessment methods for the central parts

- Identify circularity potentials

- Lifetime, functionality/efficiency and “End of life” of the coating system.

- Effect on the environment.

What does it mean for society: It can be used to rank coating systems on a sustainability scale - and by then help guiding the whole coating industry to develop a more sustainable future.

Project period

The Hempel Foundation and the Technical University of Denmark (DTU)

The project runs from 15 October 2021 - 14 October 2024.

Supervisors

- Kim Dam-Johansen

- Michael Hauschild

Contact

Mads Juhl Postdoc Department of Chemical and Biochemical Engineering madju@kt.dtu.dk

Contact

Kim Dam-Johansen Professor, Head of Department Department of Chemical and Biochemical Engineering KDJ@kt.dtu.dk

Contact

Michael Zwicky Hauschild Professor Department of Environmental and Resource Engineering Phone: +45 45254664 mzha@dtu.dk

Background

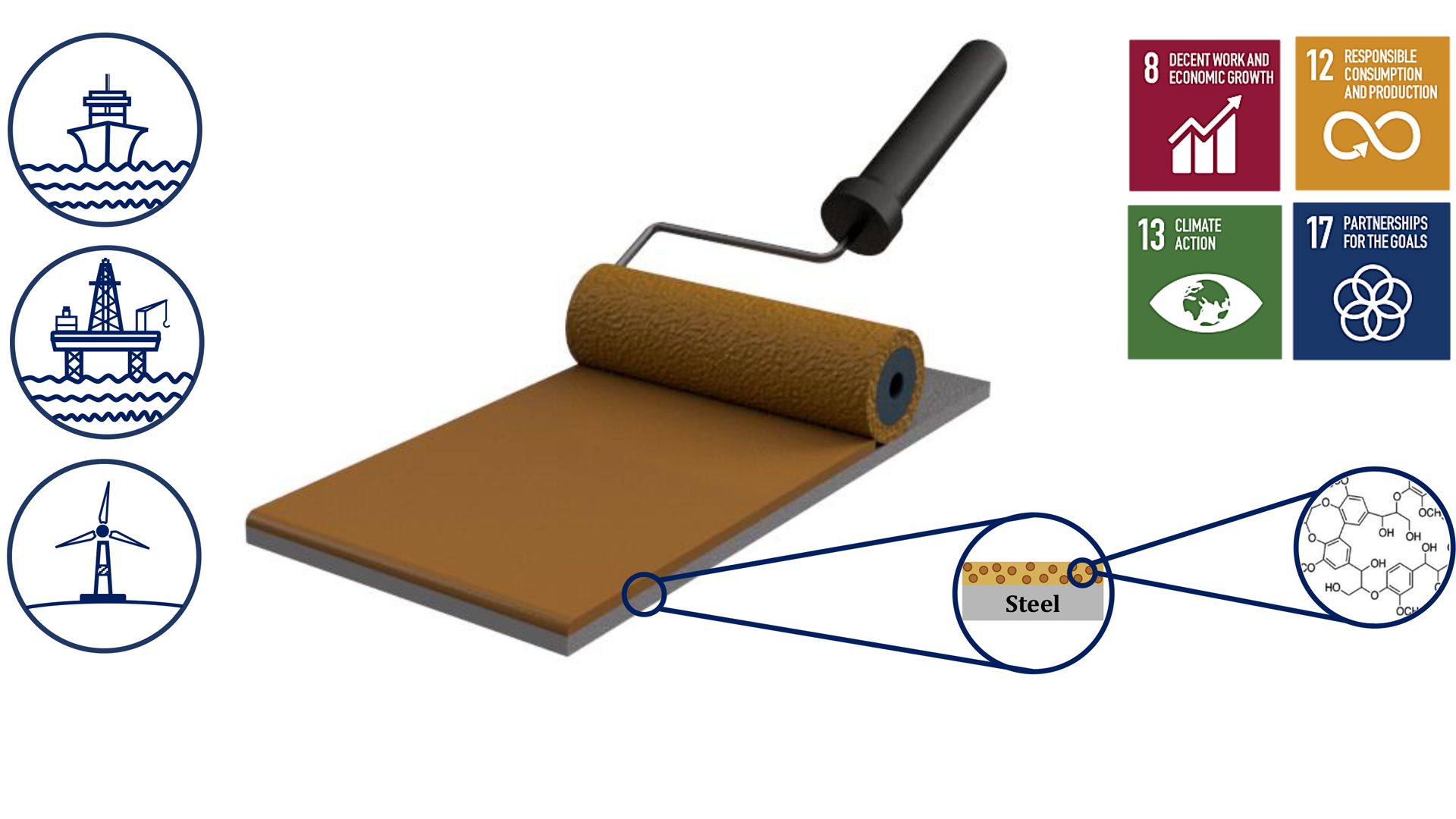

Large steel structures, such as ships, wind turbine towers and oil rigs, are protected by multi-layer anticorrosive coating systems to avoid structural failure. However, these anticorrosive coatings are based on fossil fuels. Therefore, there is a rising demand for incorporating sustainability in the life cycle of coatings to lower the carbon footprint.

The project

The project focuses on replacing part of the fossil fuel-based binders in coatings with bio-based materials, derived from plants or trees, including:

- Identification of suitable bio-based materials for next-generation green coatings

- Formulation and testing of bio-based coatings

- Accelerated exposure testing of bio-based coatings (salt spray and UV radiation: to examine the corrosion resistance properties and durability)

- Sustainability evaluation of the developed bio-based coatings

- Upscaling from lab to commercial-scale production of bio-based coatings

Funding

Nordic Five Tech and the Hempel Foundation.

The project runs from 01 September 2021- 31 August 2024.

Supervisors

- Søren Kiil (main supervisor)

- Narayanan Rajagopalan (co-supervisor)

- Mats Johansson, KTH Royal Institute of Technology (co-supervisor)

Contact

Contact

Søren Kiil Professor Department of Chemical and Biochemical Engineering sk@kt.dtu.dk

The proposed research methodology not only aims at designing and developing a commercial grade novel functional pigment but also suggests an alternative for incorporating a sustainable, green, large scale lignin based raw material into coatings.

The chemistry behind the interaction of modified lignin with different metal cations will be analyzed. Moreover, the modification will allow the lignin to be incorporated into the coating formulations with a superior distribution and dispersion. Owing to the many superior attributes of lignin, the anti-corrosive mechanism of the proposed transition metal complexes of lignin in coatings will be assessed.

Funding

The Hempel Foundation and the Technical University of Denmark (DTU). The project runs from 1 December 2021 - 30 November 2024.

Supervisors

Contact

Tushar Narayan Chaudhari Student Students s220699@student.dtu.dk

Contact

Kim Dam-Johansen Professor, Head of Department Department of Chemical and Biochemical Engineering KDJ@kt.dtu.dk

Objective

The objective of the project will be to derivatize lignin which will enable its use in coating systems. This could be either as a filler, an active part of the binder system or as an antioxidative agent for anti-corrosive coatings. Several modifications will be targeted in this project either through chemical or enzymatic processes, which subsequently will be applied to coating systems and evaluated.

Background

For a more sustainable future within coating applications, a transition from fossil-based to renewable raw materials has to be realized. Lignin, which is a renewable resource from trees and currently a by-product from the pulp and paper industry, could potentially be of high value in coating applications, but requires derivatization to enable increased compatibility within coating systems.

The project

Lignin derivatization will be achieved through use of chemical and enzymatic processes which will enable its use in coatings. Chemical modifications of lignin are of interest to increase compatibility with existing coating systems or for its deritivization to be part of the binder system for a higher biobased content in the final coating. In this project, enzymatic lignin modification will be utilized for its selectivity, which will allow for lignin to be used as an anticorrosive agent in a final coating system.

Funding

The Hempel Foundation and the Technical University of Denmark (DTU). The project runs from 1 October 2020 - 30 September 2023.

Supervisors

- Anders Egede Daugaard (main supervisor)

- Kim Dam-Johansen (co-supervisor)

- John Woodley (co-supervisor)

Contact

Contact

Anders Egede Daugaard Professor Department of Chemical and Biochemical Engineering adt@kt.dtu.dk